Ensuring Proper Tensioning and Securing of Cable Railings for Heavy Loads

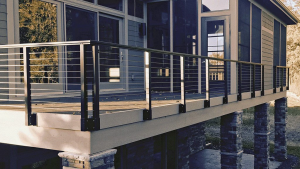

Cable railings have gained immense popularity in recent years due to their modern and minimalist design, offering unobstructed views while maintaining safety. However, the effectiveness of cable railings largely depends on the proper tensioning and securing of cables, especially when dealing with heavy loads.

Choose the Right Materials

The foundation of a robust cable railing system begins with selecting the right materials. Stainless steel cables are the preferred choice because of their durability and resistance to corrosion. The two main grades suitable for cable railings are 316 and 304 stainless steel. Grade 316 is the best choice for outdoor applications and areas with exposure to saltwater, as it offers superior corrosion resistance.

Determine Cable Spacing and Tension

Proper cable spacing and tension are critical factors in ensuring the structural integrity of your cable railing system. The spacing between cables should adhere to local building codes and industry standards. Typically, cables are spaced 3 inches apart for residential applications, but this may vary depending on the specific requirements in your area.

To determine the correct tension for your cables, use a cable tension gauge or a specialized tensioning tool. Proper tensioning ensures that the cables can handle heavy loads without sagging or becoming loose. It’s important to note that the tensioning process may require periodic adjustments over time due to temperature fluctuations and cable stretching.

Install Proper Anchors and End Fittings

The anchor points and end fittings play a crucial role in the overall strength of your cable railing system. Ensure that you use high-quality anchors, such as lag screws or bolts, to secure the railing posts to the underlying structure. These anchor points should be robust enough to handle the anticipated loads.

For the ends of the cables, use cable fittings specifically designed for cable railings. Swage fittings or compression fittings are common choices, and they should be properly crimped or swaged to the cable ends to create a secure connection.

Regularly Inspect and Maintain

Even a well-installed cable railing system can deteriorate over time if not properly maintained. Regular inspections are essential to identify any issues and ensure the system remains secure. Inspect cables for signs of corrosion or damage and replace any compromised components promptly.

Additionally, lubricate the fittings periodically to prevent rust and ensure smooth tension adjustments. Cleaning the cables with a mild detergent and water can also help maintain their appearance.

Consider Professional Installation

While some homeowners may opt for DIY cable railing installations, it’s often advisable to hire a professional contractor, especially for systems intended to withstand heavy loads. Professional installers have the expertise to ensure that all aspects of the installation, including tensioning and securing, are carried out correctly and in compliance with local building codes.

Proper tensioning and securing of cables in cable railings are essential for ensuring the safety and durability of your railing system, especially when dealing with heavy loads. By choosing the right materials, spacing and tensioning the cables correctly, using high-quality anchors and fittings, conducting regular inspections, and considering professional installation, you can enjoy the aesthetic appeal and functional reliability of cable railings for years to come. Remember that safety should always be a top priority when installing and maintaining cable railings.

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com