Introduction to the Mirror Polishing Process of Stainless Steel

Introduction:

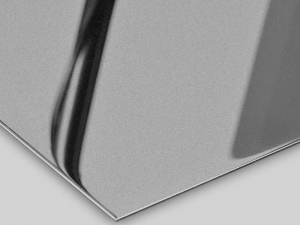

Mirror polishing, also known as mechanical polishing or buffing, is a surface finishing technique employed to enhance the aesthetic appeal and corrosion resistance of stainless steel. This process involves removing surface imperfections, such as scratches, stains, and roughness, to achieve a highly reflective and smooth mirror-like finish. The mirror polishing process not only enhances the visual appearance of stainless steel but also improves its cleanability and hygiene, making it suitable for various applications in industries such as architecture, automotive, and food processing.

Surface Preparation:

The mirror polishing process begins with thorough surface preparation. Any existing coatings, oils, or contaminants on the stainless steel surface are removed through cleaning and degreasing. This step ensures that the subsequent polishing process can effectively eliminate imperfections and achieve the desired mirror finish.

Grinding and Smoothening:

Grinding and Smoothening:

After surface preparation, the stainless steel undergoes grinding to eliminate surface irregularities. Coarse abrasives, such as grinding belts or wheels, are initially used to level the surface and remove deep scratches or dents. As the process progresses, finer abrasives are employed to achieve a smoother surface texture. This gradual refinement of abrasives helps eliminate the scratches left by the previous abrasive, resulting in a progressively smoother finish.

Polishing:

Once the grinding stage is complete, the stainless steel is ready for the polishing phase. Polishing involves using progressively finer abrasives, often in the form of polishing wheels or belts, along with polishing compounds. These compounds contain abrasive particles suspended in a lubricating medium, aiding in the removal of smaller imperfections and enhancing the surface shine. The polishing process is carried out using specific techniques, such as rotating or oscillating motions, to ensure uniformity and consistent results.

Buffing and Finishing:

In the final stages of the mirror polishing process, buffing and finishing techniques are applied to achieve the desired mirror-like reflective surface. Soft buffing wheels or pads, combined with a polishing compound, are used to further refine the surface and enhance its smoothness. This step helps eliminate any remaining fine scratches and imparts a high-gloss finish.

Cleaning and Protection:

After mirror polishing, it is crucial to clean the stainless steel surface thoroughly to remove any residues or compounds used during the polishing process. Additionally, a protective coating or film may be applied to safeguard the polished surface from oxidation, fingerprints, and other contaminants. This protective layer helps maintain the mirror finish and prolongs the lifespan of the polished stainless steel.

The mirror polishing process is a meticulous and multi-step technique employed to achieve a reflective and smooth surface finish on stainless steel. By removing imperfections and enhancing the aesthetic appeal, mirror polishing adds value to stainless steel, making it desirable for a wide range of applications. The mirror polishing process enhances both the visual appeal and functional performance of stainless steel.

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com