Description of the Satin Brushed Finish Process on Stainless Steel

Stainless steel is a popular material used in many applications, from kitchen appliances to medical equipment. One of the most common finishes for stainless steel is the satin brushed finish. This finish is achieved through a process that involves abrasive materials and a specific technique.

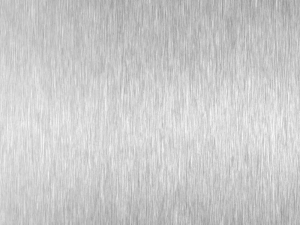

The satin finish on stainless steel is a non-reflective, low-gloss finish that gives the metal a soft, smooth appearance. This finish is achieved by using abrasive materials to create a uniform, fine-grained surface texture. The process involves using a combination of abrasive belts, pads, and wheels to remove the surface layer of the stainless steel, leaving a smooth, satin finish.

The first step in the satin drawing process is to thoroughly clean the stainless steel surface. This ensures that there are no dirt, debris, or oils on the surface that could interfere with the abrasive process. Once the surface is clean, the abrasive materials are applied to the surface using a specific technique.

The abrasive materials used for the satin finish process on stainless steel can vary depending on the desired finish. For example, a coarser abrasive material would be used to create a more textured finish, while a finer abrasive material would be used for a smoother finish.

The satin brushed finish process on stainless steel is a delicate and precise process that requires skill and experience. The process involves carefully controlling the speed, pressure, and direction of the abrasive materials to achieve the desired finish. The final product is a beautiful, soft, satin finish that is both durable and aesthetically pleasing.

The satin brushed finish process on stainless steel is a popular finish that is used in many applications. This finish is achieved through a precise and delicate process that involves using abrasive materials and a specific technique. The result is a beautiful, soft, satin finish that is both durable and aesthetically pleasing.

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com