Pre-Galvanizing Treatment: Essential Steps for Optimal Results

Before galvanizing, steel surfaces must undergo proper treatment to ensure strong adhesion and long-lasting protection. The preparation process removes contaminants, ensuring the zinc coating bonds effectively with the steel.

1. Degreasing (Cleaning the Surface)

Removes oils, grease, and other organic contaminants using an alkaline or acidic cleaning solution.

Ensures no residues interfere with the galvanizing process.

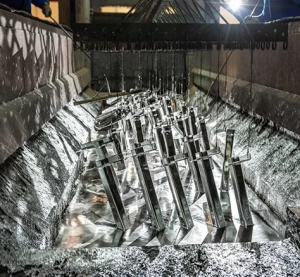

2. Pickling

Steel is dipped in an acid bath (usually hydrochloric or sulfuric acid) to remove rust, mill scale, and oxidation.

Creates a clean, reactive surface for zinc adhesion.

3. Rinsing

After pickling, the steel is thoroughly rinsed with water to remove acid residues.

Prevents contamination in the zinc bath.

4. Fluxing

The steel is dipped in a flux solution (e.g., zinc ammonium chloride) to prevent oxidation before immersion in molten zinc.

Enhances zinc bonding and ensures an even coating.

5. Drying

Steel parts are dried to remove moisture, preventing splattering when immersed in molten zinc.

Proper pre-treatment ensures a smooth, durable, and corrosion-resistant galvanized coating, making the steel suitable for long-term use in demanding environments.

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com