The Comparison of Zamak Glass Clamp & Stainless Steel Glass Clamp

ZAMAK is made up of aluminium, magnesium, copper and zinc, and is a type of aluminium alloy.

Zinc alloys

Zinc alloys have a high relative density. Casting performance is excellent, can be die-cast into precision parts with complex shapes and thin wall, the surface is smooth. Surface treatment can be electroplating, polishing, spraying, painting and grinding, etc. When melting and die casting, zinc alloy does not absorb iron, does not corrode and not stick to the mold. It also has a low melting point and is easy to die cast. The disadvantage is that the surface of zinc alloy die casting is easy to bubble.

ZAMAK

Several common types of the zinc alloys are #3, #2, #5, and #7. Typically #3 is the preferred when considering zinc die-casting. Over 70% of all Zinc die-casting are made from #3. ZAMAK can be painted, plated, or coated to provide an attractive look and texture.

If you need to choose zinc alloy for die casting, all options are considered. ZAMAK alloy is similar to ZA alloy in composition, but it has better application results in different applications. ZAMAK alloys are typically used in hot chamber die-casting, whereas ZA requires a special melting procedure and is cast using a cold chamber die-casting process similar to aluminum.

|

|

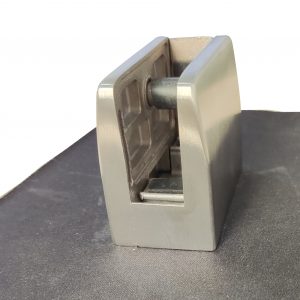

| Sqaure ZAMAK glass clamp-flat | |

Stainless steel advantages: better welding performance.

Corrosion resistance: Most stainless steel products have good corrosion resistance. When the number of chromium atoms in steel is not less than 12.5%, the electrode potential of steel can be changed from negative potential to positive electrode potential. It prevents electrochemical corrosion.

Heat resistance: The stainless steel can still maintain its excellent physical and mechanical properties at high temperatures. Although there is a film on the surface of stainless steel, but some reasons will lead to the film by constant destruction, oxygen atoms in the air or liquid will continue to come out of the resolution, the formation of loose iron oxide, the metal surface is subject to constant corrosion.

|

|

| 55×65 square glass clamp-flat | |

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com