The Essential Guide to Stainless Steel Wire Nets: Applications, Benefits, and Selection

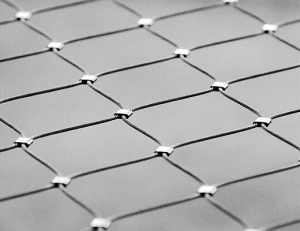

Stainless steel wire nets, also known as stainless steel wire mesh or stainless steel wire screens, are versatile materials used in a myriad of applications across various industries. Known for their durability, strength, and corrosion resistance, these nets play a crucial role in both industrial and everyday applications.

-300x300.png) 1. Understanding Stainless Steel Wire Nets

1. Understanding Stainless Steel Wire Nets

Stainless steel wire nets are made from woven or welded stainless steel wires. The configuration can vary significantly depending on the purpose, ranging from fine mesh used in filtration to coarse mesh used in structural applications. The most common grades of stainless steel used are 304 and 316, both of which offer excellent corrosion resistance with the latter providing higher resistance to chemicals and saline environments.

2. Key Properties

Durability: Stainless steel wire nets are highly durable and capable of withstanding extreme conditions without degradation.

Corrosion Resistance: One of the primary benefits of stainless steel is its resistance to rust and oxidation, making it ideal for use in harsh environments.

Heat Resistance: Stainless steel can withstand high temperatures, which is crucial for applications involving heat.

Hygiene: Stainless steel is easy to clean and sanitize, which is why it is commonly used in food processing, medical, and pharmaceutical applications.

3. Applications of Stainless Steel Wire Nets

3. Applications of Stainless Steel Wire Nets

Filtration: Used in both industrial and residential filtration systems to separate solids from liquids or gases.

Architectural Uses: Often used in facades, panels, and shading devices due to their aesthetic appeal and structural integrity.

Agriculture: Employed in barriers or enclosures to protect crops or contain animals.

Industrial Screening: Utilized in mining, chemical processing, and other industries for sorting and screening processes.

Safety and Security: Provides barriers or enclosures in machinery parts, buildings, and other structures to enhance safety and security.

4. Benefits of Using Stainless Steel Wire Nets

Longevity: The nets are designed to last, reducing the need for frequent replacements and lowering maintenance costs.

Versatility: Can be used in a variety of applications and tailored to meet specific needs.

Aesthetic Flexibility: Stainless steel has a modern look that can complement various architectural styles.

Environmental Resistance: Ideal for outdoor or marine environments where other materials might fail.

5. Choosing the Right Stainless Steel Wire Net

Selecting the appropriate stainless steel wire net involves considering several factors:

Environment: The chemical and physical environment in which the net will be used can determine the grade of stainless steel required.

Mesh Size and Wire Diameter: These should be chosen based on the size of the particles that need to be filtered or the type of stress the net must endure.

Weave Type: Different weave types offer different characteristics. For example, a plain weave is most common and provides a balance of strength and openness, while twilled weaves offer higher density and are suited for finer filtration.

Application Specifics: Consider aspects like load-bearing requirements, aesthetic preferences, and exposure conditions.

6. Maintenance and Care

Maintenance of stainless steel wire nets is relatively straightforward. Regular cleaning to remove debris and prevent build-up, combined with periodic inspections for structural integrity, will extend the life of these nets. In highly corrosive environments, more frequent cleaning or using higher grades of stainless steel can prevent degradation.

Stainless steel wire nets are indispensable in modern technology and construction, offering unmatched durability, versatility, and resistance to harsh conditions. Whether used in industrial sieving and sorting, architectural aesthetics, or safety implementations, these nets provide solutions that balance efficiency, functionality, and cost-effectiveness.

+86 159 6420 9667

+86 159 6420 9667  sales@haxrailing.com

sales@haxrailing.com